Day in the life of an ICA Engineer

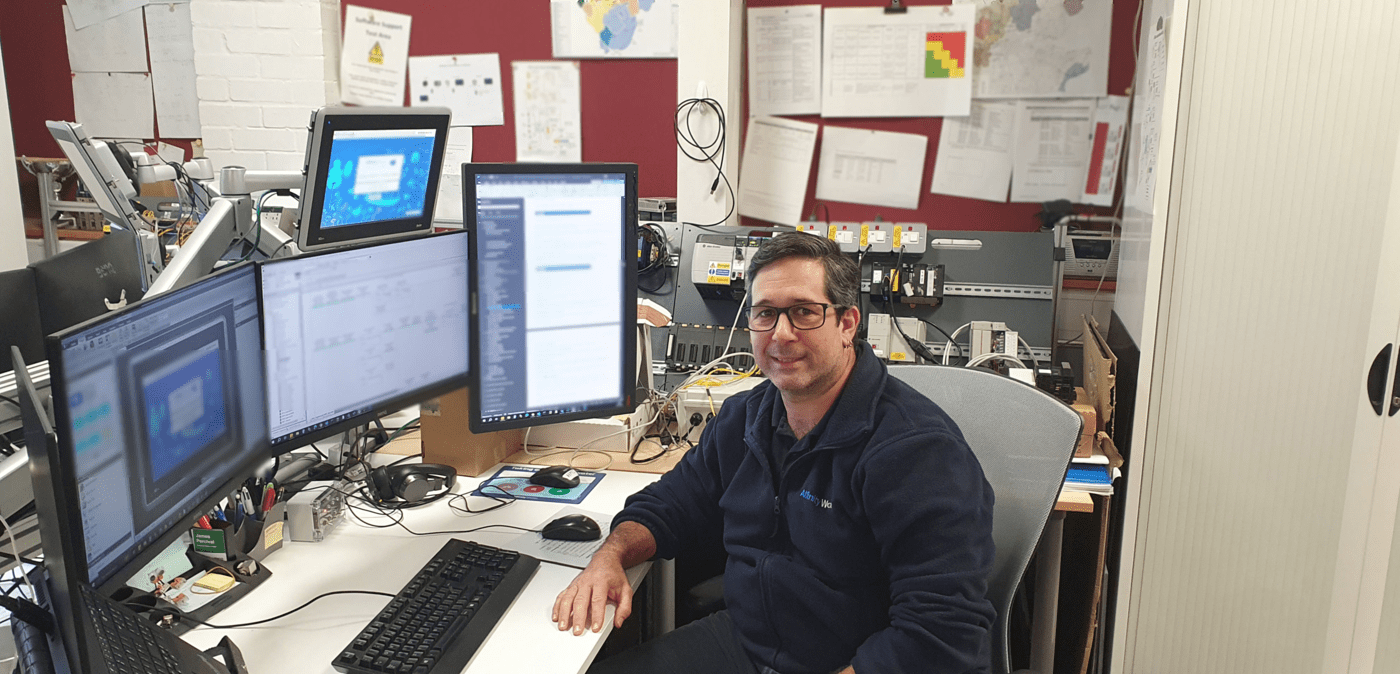

We're looking to find the perfect fit for an Instrumentation, Control and Automation (ICA) Engineer. We caught up with Dallas, who joined the team a couple of years ago, to find out more about what he does day-to-day to give you a flavour of what the role involves.

Can you tell us what your role involves?

The ICA Engineer role covers a lot of bases across the company, our primary role is supporting production in keeping the water flowing by providing technical support and assisting fault finding with the technicians on site, as well as developing code to manage changes to processes or conditions of the water supply.

This includes keeping the ICA standards up to date, region production investment management meetings, hazard during operation studies (before a new process installation or modification) and risk and value studies.

We also get involved with the asset team to help manage system integrators or to develop and deliver inhouse PLC (programmable logic controller) code for upgrades and additions to existing sites as well as completely new sites and processes.

What does a typical day look like?

Most days I start at the Roestock site in Colney Heath with a cup of coffee and from there the day can go anyway.

When I am working on a project, I am based in the office for around 3-6 weeks, but as we are a small team responding to site issues take precedence over long term projects, this means I could be heading anywhere within the four corners of the company from Sundon Reservoir to Denge and Clacton to Great Missenden. Generally, we can resolve most issues over the phone while we integrate the code and work with a technician on site.

What’s the most challenging part of your role?

As water is not where I have come from, learning about all the different processes and how sites interact with each other can be quite a challenge and I have to rely on the technicians with their local site knowledge to work out how things are meant to be working and what needs to be done to get back to that happy place.

Also Omron BCD (Binary Coded Decimal) a hexadecimal number that only goes up to 9999 and pretends to be a decimal…..

What do you enjoy the most?

Getting out and about and visiting all the different sites across the company.

Working in a team that all have very similar ideas on how we are to get the best from the PLCs and collaborating on problems as a team.

What’s the best part of working in the Production team?

The ability to cover all of the sites that we have, and not being stuck in an office all the time.

One piece of advice you’d give to someone applying?

It’s not all about what you know (but you do need to know your stuff).

The willingness to learn and accept a greater plan goes along way when you are working in a team.